Meadowlark Optics’ Retardance Measurement Station, Model TB1000, is the first commercial product for high precision measurements of waveplates. Customer demand triggered the development of the TB1000. This turnkey, fully-enclosed system measures the retardance of multi-order waveplates and same-material compound zero-order waveplates (Sapphire, Magnesium Fluoride, and Quartz).

The TB1000 is versatile and portable and can be easily moved from the R&D lab to the production floor, bringing the precision of Meadowlark Optics Metrology Services from our lab to yours. Retardance measurements are obtained in under 2 seconds with the user-friendly software in just one click. A reference retarder is included with each shipment to ensure the system is meeting the calibration as measured at the factory prior to shipping.

Optional items can be added to the TB1000. The standard system has alignment marks to assist in placement of the waveplate on the measurement bay. This area can be customized per the user’s crystal dimensions with our drop-in alignment guide, which ensures that measurements are spatially accurate each and every time.

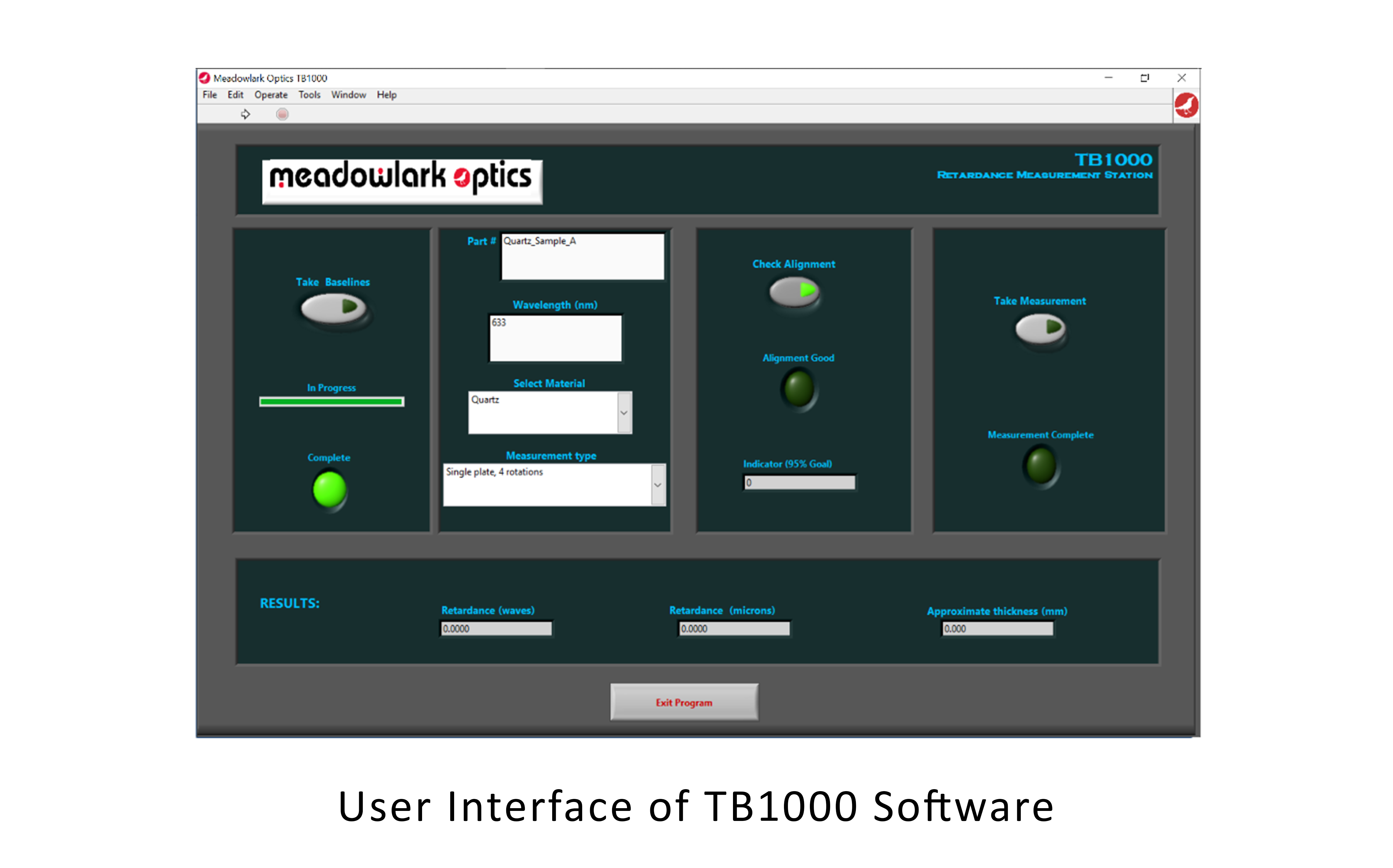

The TB1000 software is fully automated and provides user’s retardance measurements with a simple click. It only takes <2 seconds to obtain accurate, repeatable results. Due to variation in crystal structure, calculating the retardance based on the thickness of the material using only a listed birefringence can lead to errors. The TB1000 allows an end user to accurately measure the real retardance of each waveplate.

Retardance in crystals will change with temperature variation. As a rule of thumb, the retardance (in waves) for a 1 mm thick quartz retarder varies by about -0.5% per °C. For this reason, we encourage regular monitoring of air temperature around the equipment if small retardance changes are concerning. Alternatively, you can use the reference retarder included with the TB1000 to confirm accurate readings.