Product Details

Item # | Wavelength(s) | Wavefront Distortion | AR Coating | Response Time | Cooling | Mirror |

|---|---|---|---|---|---|---|

532, 635, 785, 1064 | respectively λ/7, λ/8, λ/10, λ/10 | 500-1200 | respectively ≤ 19.0, ≤ 20.0, ≤ 23.0, ≤ 33.0 | Liquid Cooling | Dielectric Mirror | |

1064, 1550 | respectively λ/10, λ/12 | 850-1650 | respectively ≤ 40.0, ≤ 55.0 | NO Liquid Cooling | NO Dielectric Mirror | |

1064, 1550 | respectively λ/10, λ/12 | 850-1650 | respectively ≤ 40.0, ≤ 55.0 | Liquid Cooling | NO Dielectric Mirror | |

1064, 1550 | respectively λ/10, λ/12 | 850-1650 | respectively ≤ 40.0, ≤ 55.0 | NO Liquid Cooling | Dielectric Mirror | |

1064, 1550 | respectively λ/10, λ/12 | 850-1650 | respectively ≤ 40.0, ≤ 55.0 | Liquid Cooling | Dielectric Mirror |

1920 x 1200 Spatial Light Modulator

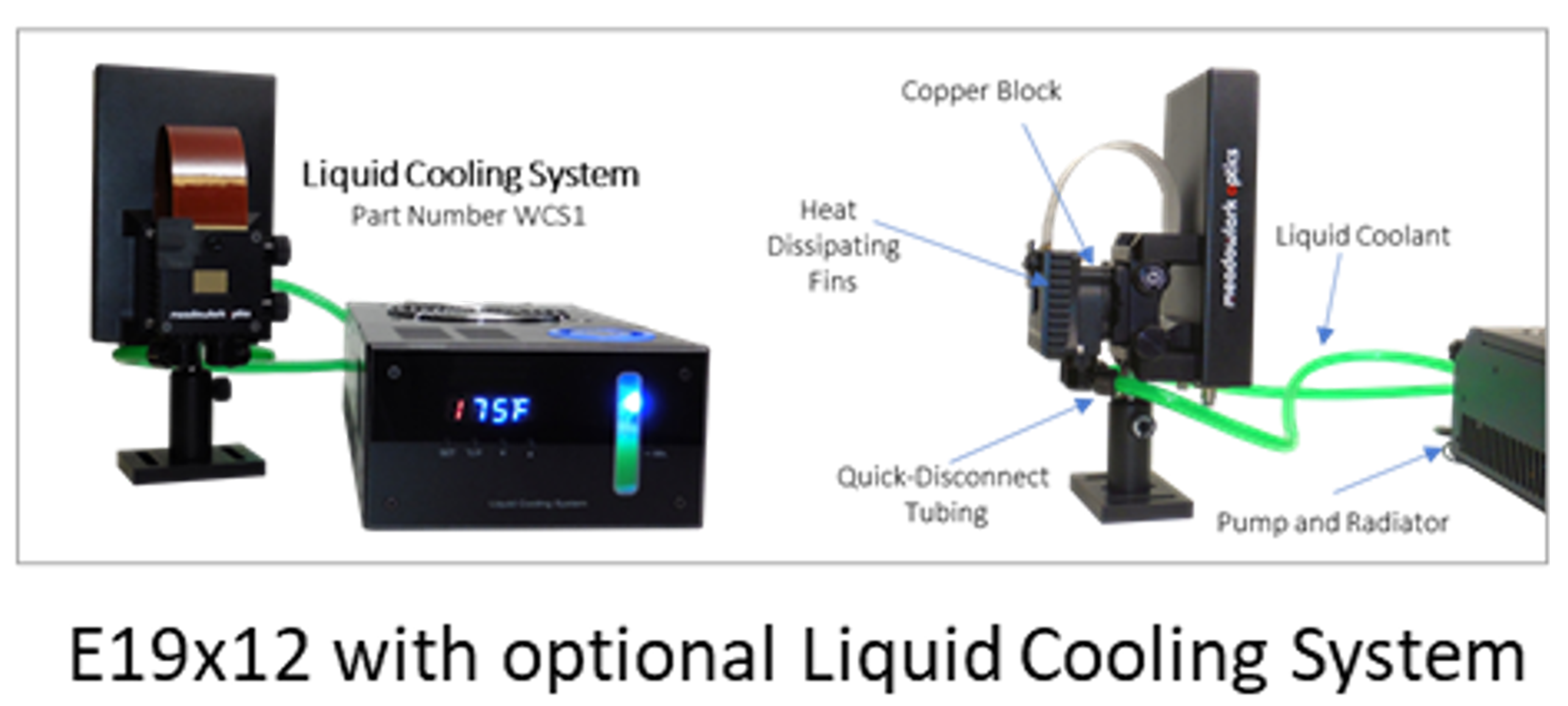

Meadowlark Optics is pleased to introduce our latest 1920 x 1200 Spatial Light Modulator (SLM) options. Don’t let the “E-Series” name fool you; with improved specifications over our previous model, it is anything but entry-level. It is, however, economical and ideally suited for educational labs with a limited budget. The new standard “S-Series” offers key features not previously available, including 10-bit operation, customizable dielectric mirror coatings for improved efficiency, and liquid cooling for high power applications.

Liquid Crystal on Silicon (LCoS) Spatial Light Modulators (SLMs) are uniquely designed for pure phase applications and incorporate analog data addressing with high refresh rates. This combination provides users with the fastest response times and highest phase stabilities commercially available. Phase-only SLMs can also be used for amplitude-only modulation or take advantage of the rectangular aperture for simultaneous phase and amplitude .

High Phase Stability – Meadowlark Optics is known for having the fastest SLMs with the least amount of phase ripple on the market. Our backplanes are custom designed with high refresh rates and direct analog drive schemes, resulting in phase ripple of less than 0.40%. For customers who require higher stability, custom options are available. Phase ripple is quantified by measuring the variation in intensity of the 1st order diffracted spot as compared to the mean intensity while writing a blazed phase grating to the SLM.

Diffraction Efficiency (1st-order) – This is the percentage of light measured in the 1storder when writing a linear repeating phase ramp to the SLM as compared to the light in the 0th order when no pattern is written to the SLM. Diffraction efficiency varies as a function of the number of phase levels in the phase ramp. The plot to the right shows sample 1st order diffraction efficiency measurements, as a function of the phase ramp period, taken at various wavelengths.

Hardware Interface Options – 8-Bit and 10-Bit The 1920 x 1200 SLM is offered with a 60 Hz HDMI Controller configured for 8-bits in the Economical Series, and 10-bits in the Standard Series. Both hardware options include an output trigger for synchronization.

Diffraction Efficiency (0th-order) – This is the amount of light measured in the 0th-order (dc) when the SLM is written with various solid gray levels as a percentage of the amount of light measured when the SLM is replaced with a reference mirror. This specification accounts for losses in transmission through SLM cover window coatings, diffraction due to the pixelated structure of the backplane, and either reflectivity of the aluminum pixel pads or reflectivity of the dielectric mirror design. The 0th-order diffraction efficiency will vary as a function of wavelength due to differences in coating materials and designs. It will also vary with pixel value due to the inherent change in the index of refraction of the liquid crystal that results in a change in the Fresnel reflections inside the liquid crystal cell. Most standard SLMs will range from 70 – 90%, while the dielectric mirror coated models will range from 92 – 98%.

High-Efficiency Dielectric Mirror Coating (S-Series Only) – The reflective pixel structure of a LCoS SLM backplane diffracts some light into higher orders. By adding a dielectric mirror, the pixelated structure is replaced with an optically flat surface. The dielectric stack is kept thin to minimize any drop in electric field across the LC layer to maximize response time and minimize inter-pixel crosstalk. Custom designs can be supported covering a bandwidth of up to 200 nm.

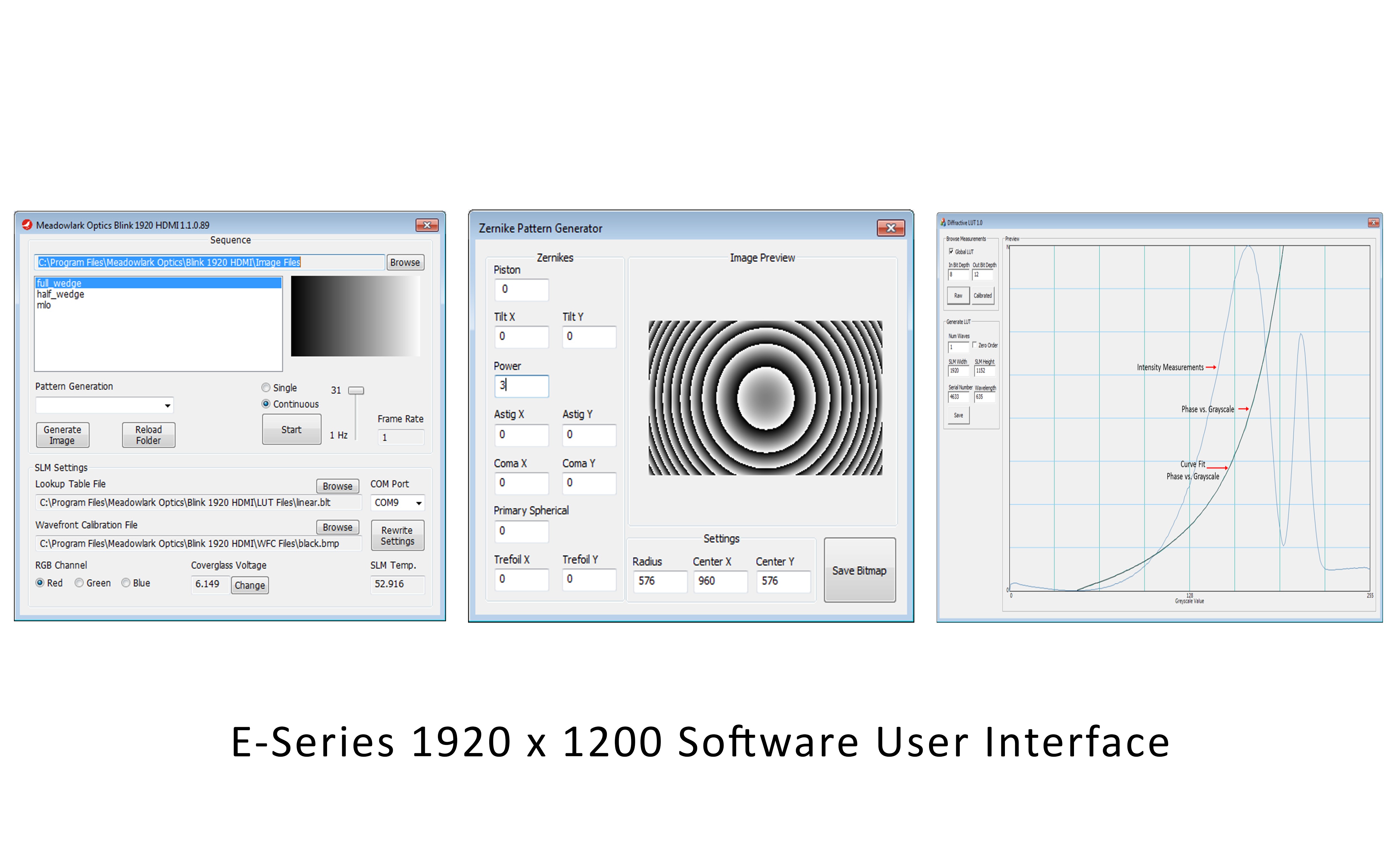

Software – Meadowlark Optics’ SLMs are supplied with a Graphical User Interface and software development kits that support LabVIEW, Matlab, Python, and C++. The software allows the user to generate images, to correct aberrations, to calibrate the global and/or regional optical response over ‘n’ waves of modulation, to sequence at a user defined frame rate, and to monitor the SLM temperature.

Calibration Kit – Using an included closed loop tool global or regional calibrations can be quickly generated and validated to account for a customer’s incident power, angle of incidence, and desired spatial frequency of pattern applied.

Image Generation Capabilities –

Bessel Beams: Spiral Phase, Fork, Concentric Rings, Axicons

Lens Functions: Cylindrical, Spherical

Gratings: Blazed, Sinusoid

Diffraction Patterns: Stripes, Checkerboard, Solid, Random Phase, Holograms, Zernike Polynomials, Superimpose Images

Resolution: 1920 x 1200 | Fill Factor: 95.6% |

| Array Size: 15.36 x 9.60 mm | 0th Order Diffraction Efficiency: 76 – 91% |

| Pixel Pitch: 8.0 x 8.0 µm | 0th Order Diffraction Efficiency: 92 – 98% (dielectric mirror) |

| Backplane Refresh: 1.35 kHz | Controller: HDMI |

Standard Calibration Wavelengths | STANDARD SPEED Liquid Crystal Response Time | Calibrated Wavefront Distortion | ||

AR Coating Range 350 – 850 nm | AR Coating Range 500 – 1200 nm | AR Coating Range 850 – 1650 nm | ||

405 nm | ≤ 13.4 ms | λ/5 | ||

532 nm | ≤ 14.0 ms | ≤ 17.0 ms | – | λ/7 |

635 nm | ≤ 14.5 ms | ≤ 17.5 ms | – | λ/8 |

785 nm | ≤ 20.5 ms | ≤ 22.5 ms | – | λ/10 |

1064 nm | – | ≤ 25.0 ms | ≤ 27.5 ms | λ/10 |

1550 nm | – | ≤ 43.0 ms | ≤ 45.0 ms | λ/12 |